Aluminium Degassing Tablets Manufacturer

Jagannath Company, backed by over 35 years of metallurgical expertise and guided by IIT-engineered innovations, offers a premium range of Aluminium Degassing Tablets designed to ensure optimal melt quality, structural integrity, and casting performance. These tablets are extensively used across extrusion, die-casting, and foundry operations to eliminate hydrogen gas and inclusions from molten aluminium.

Professional-Grade Degassing for Premium Aluminium Alloys

Our Aluminium Degassing Tablets are scientifically formulated to release active gases that react within the molten aluminium, ensuring thorough removal of dissolved hydrogen and suspended oxides. The result is a cleaner melt with reduced porosity, enhanced mechanical properties, and improved surface finish in final products.

Distinguished Features of Our Degassing Tablets:

Eliminates Hydrogen Efficiently: Ensures controlled gas removal for porosity-free castings.

No External Nitrogen Required: Functions independently without auxiliary inert gas systems.

Superior Metal Flowability: Enhances casting behavior by reducing surface tension and impurities.

Non-Toxic & Odor-Free: Eco-conscious, operator-friendly formulation with zero irritating emissions.

Deep Dross Removal: Pulls sludge and impurities from furnace bottoms for a refined melt pool.

Technical Benefits and Operational Advantages:

Zero Rejection Rate: Achieves high dimensional accuracy and consistency in casting outputs.

Enhanced Visual & Structural Quality: Increases brightness, strength, and ductility of billets and profiles.

Improved Machinability: Reduces hard spots, enabling smoother cutting and tooling efficiency.

Increased Yield Strength: Optimizes tensile performance with improved elongation characteristics.

Time-Efficient Processing: Cuts down degassing cycle time by 15–20 minutes without quality compromise.

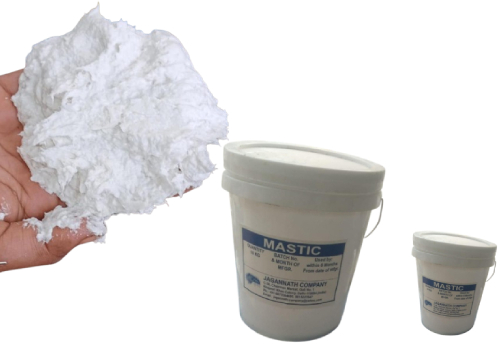

Packaging & Customization Options

Jagannath Company provides Aluminium Degassing Tablets in customized sizes and packaging formats to match varied furnace capacities and melt chemistries. Our team offers technical consultancy to determine optimal addition rates and tablet integration for your specific casting setup.

Industries & Application Scope:

Aluminium Extrusion Billet Plants

Automotive and Aerospace Foundries

High-Precision Die-Casting Units

Aluminium Alloy Recycling and Refining Facilities

Non-Ferrous Metallurgical Laboratories and Research Institutes

Why Industry Leaders Trust Jagannath Company

35+ Years of Proven Experience: Serving the aluminium metallurgy sector with field-validated results.

IIT-Metallurgist Backing: Products developed under advanced metallurgical research and expertise.

In-House Manufacturing: Full control over quality assurance, traceability, and supply chain integrity.

Client-Focused Solutions: Technical support from selection to process optimization and implementation.

Optimize Melt Quality with Confidence

Jagannath Company’s Aluminium Degassing Tablets are trusted by leading aluminium processors for their consistency, safety, and metallurgical effectiveness. Whether you are upgrading melt quality or improving casting economics, our solutions bring measurable performance gains across your operations.

Contact Us

Company: Jagannath Company

Email: jagannath.company@yahoo.com

Phone: +91-98733 84650