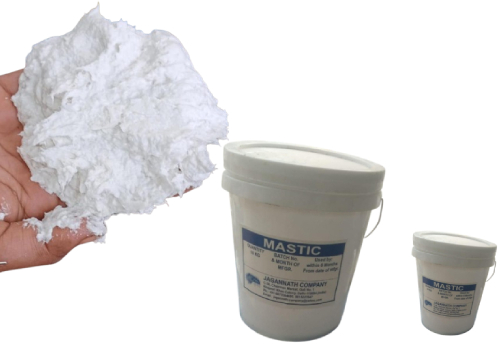

Liquid Nitriding Salts

Jagannath Company is a trusted manufacturer of high-performance Liquid Nitriding Salts, formulated for superior case hardening and wear resistance. Our proprietary salt blends - HQ 2, HQ 4, and K2S - are developed as advanced equivalents to industry-standard Tuff Triding and Sursulf Salts (CR2, CR4). These nitriding formulations are widely used in the heat treatment of steel components to enhance surface hardness, corrosion resistance, and fatigue strength.

Advanced Salt Technology for Surface Engineering

Our liquid nitriding salts facilitate a controlled diffusion of nitrogen and carbon atoms into the steel surface through a low-temperature bath. The result is a hard, wear-resistant outer layer with minimal dimensional distortion - perfect for precision-engineered components in critical applications.

HQ 2 Nitriding Salt

HQ 2 is designed for achieving high surface hardness and exceptional fatigue resistance in alloy and carbon steels. This salt ensures a uniform diffusion layer and is ideal for critical automotive components, such as gears, shafts, and cam parts.

- Best For: Precision automotive parts, bearings, and high-performance tools.

- Key Advantage: High surface hardness with excellent wear and corrosion resistance, making it a direct alternative to CR2 (Tuff Triding) formulations.

- Recommended Process: Suitable for batch nitriding furnaces and continuous salt baths, ensuring consistent results in high-volume production.

HQ 4 Nitriding Salt

HQ 4 is formulated for applications demanding a deeper and harder nitrided layer, especially in die and tool steels. It provides superior dimensional stability and is suited for complex-shaped components requiring precision and high wear resistance.

- Best For: Tool and die components, cutting tools, high-load bearing parts, and wear-critical machinery.

- Key Advantage: Deep nitriding case with exceptional thermal and mechanical properties, making it a robust replacement for CR4 (Sursulf) salts.

- Recommended Process: Compatible with both open and sealed salt bath furnaces, offering flexibility in heat treatment setups.

K2S Nitriding Salt

K2S is a high-efficiency nitriding salt blend optimized for enhanced corrosion resistance and smooth surface finish. It is particularly suitable for stainless steels and components requiring superior passivation against aggressive environments.

- Best For: Stainless steel components, surgical instruments, textile machinery parts, and components exposed to harsh conditions.

- Key Advantage: Produces a bright, clean surface with enhanced corrosion protection and uniform nitrided layer.

- Recommended Process: Ideal for continuous nitriding lines and high-output production systems demanding consistent quality.

Key Features of Our Liquid Nitriding Salts:

- Formulated Equivalents: HQ 2, HQ 4, and K2S match the performance of CR2, CR4 (Tuff Triding & Sursulf).

- Superior Surface Hardness: Enhances fatigue life and abrasion resistance.

- Low Temperature Process: Maintains core properties with minimal distortion.

- Corrosion Resistance: Improves surface passivation and reduces rusting.

- Uniform Case Depth: Controlled diffusion depth across components.

Customization Options

We offer tailored nitriding salt solutions to match specific metallurgical requirements, furnace setups, and part geometries. Our salts are compatible with both batch and continuous salt bath installations.

Application Areas:

- Automotive Gear Components

- Tool and Die Industry

- Bearings and Shafts

- Textile and Surgical Instruments

- Precision Machine Parts

Why Choose Jagannath Company?

- IIT-Engineered Formulations: Developed with metallurgical insights from IIT experts.

- Zero Leakage Plants: Complete nitriding plant design, installation & support.

- Cost-Effective & Reliable: Proven performance at affordable pricing.

- All-In-House Production: Ensures quality, consistency, and timely delivery.

Upgrade Your Heat Treatment Process

Jagannath Company's Liquid Nitriding Salts offer a robust and economical solution for surface engineering. Replace CR2 and CR4 with our HQ-series salts and experience unmatched nitriding efficiency and metallurgical precision.

Contact Us

Company: Jagannath Company

Email: jagannath.company@yahoo.com

Phone: +91-98733 84650