Best Foundry Chemicals Dealers in India | Jagannath Company

Aug-23-2025

The Unsung Heroes of Metal Casting: Choosing the Right Foundry Chemicals Dealer in India

Introduction

Behind every strong, precisely shaped metal casting lies a world of science and subtle craftsmanship. It's easy to marvel at the final product—a gleaming engine part or a finely detailed machine component—but very few appreciate the quiet power of foundry chemicals in shaping them.

Foundries are pressure situations. Every choice, every material counts. And when it comes to chemicals such as foundry additives, graphite coatings, and core binders, there is no margin for mistake. That's why selecting the correct dealer isn't merely a buying choice—it's a strategic alliance that could decide the quality, consistency, and dependability of your entire operation.

The Backbone of Every Foundry: Chemicals That Make It All Possible

If you work in the world of metal casting, you understand that the process is far more than melting metal and casting it into forms. It's a chemistry of interactions, temperature control, mold preparation, and finishing touches.

Let's learn about some of the major elements:

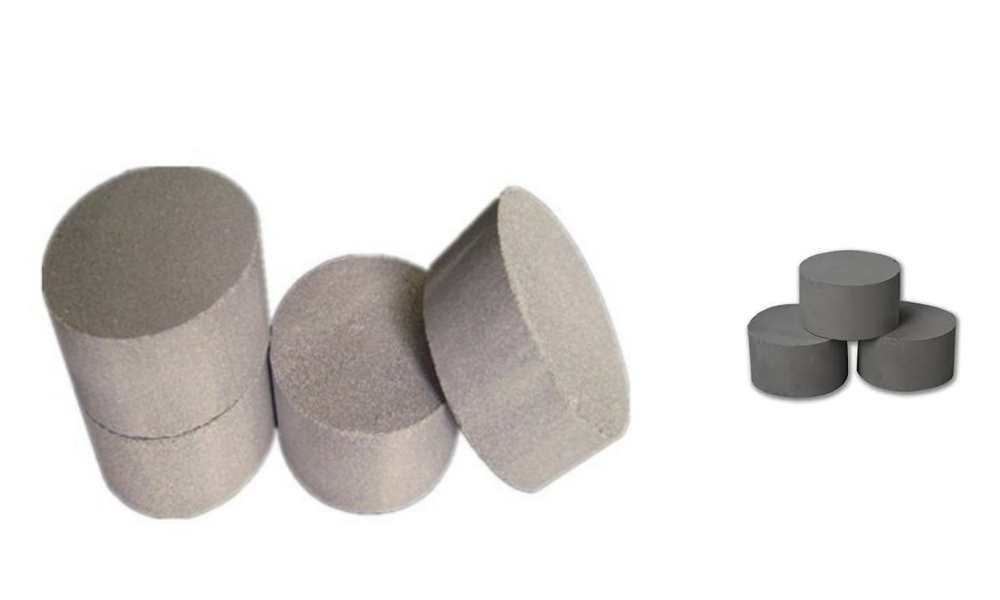

1. Foundry Additives

These are the behind-the-scenes boosters. Additives regulate shrinkage, enhance fluidity, promote metal cleanliness, and improve the microstructure of the finished product. Whether it's cast iron or steel, the optimal additive combination prevents defects like porosity and cold shuts from occurring.

2. Graphite Coatings

Graphite coatings impart surface finish enhancement and thermal resistance. Used within cores and molds, they form a non-stick lubricated barrier that provides smoother casting surfaces. They are crucial in precision work to reduce friction and support metal flow.

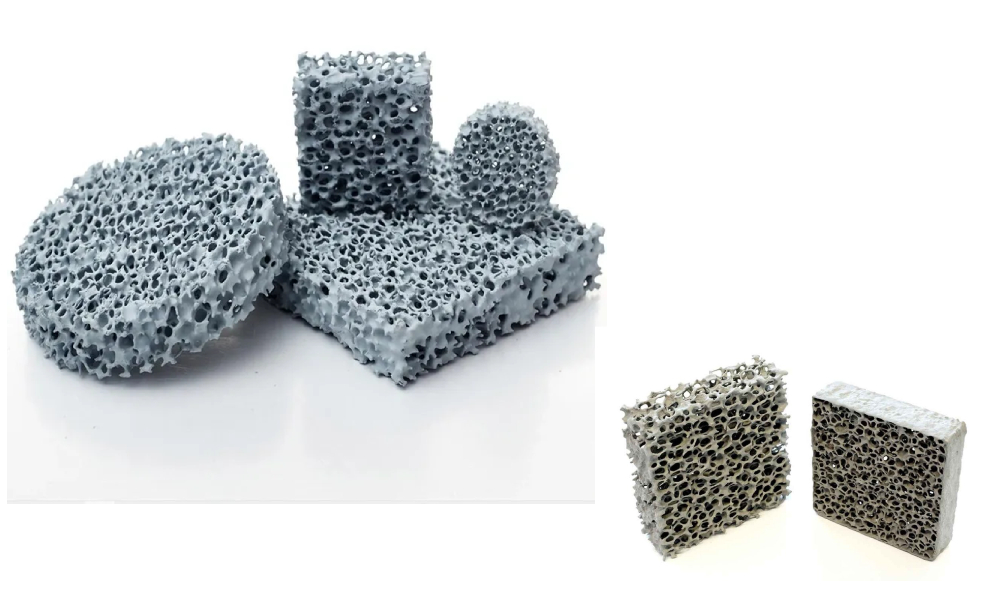

3. Core Binders

Cores, frequently sand in composition, shape out internal cavities in castings. They are bound together by binders. Regardless of whether you're employing organic or inorganic binders, the collapsibility, strength, and gas generation profile of these materials will decide how easily a core may be pulled out cleanly and how well it retains its shape in the pour.

What Makes a Dealer Stand Out?

With India's manufacturing industry booming, demand for high-quality castings—and the chemicals that enable them—is increasing fast. So, how do you find the right foundry chemicals dealer?

Quality and Purity of Products

Unstable chemical makeup causes casting imperfections. A good dealer guarantees each batch is to spec, tested, and traceable. Binders, coatings, or fluxes—purity matters.

Technical Knowledge and Support

You're not purchasing chemicals; you're purchasing knowledge. An excellent dealer ought to be able to troubleshoot problems, suggest substitute products when needed, and assist you in streamlining your process.

Delivery Reliability

Foundry schedules are lean. Holdups in supply can shut down entire operations. A reliable partner is one who follows through consistently, with strong logistics to uphold even distant or high-volume sites.

Why Established Dealers are Preferred by Foundries in India

India's foundry sector is diversified. From auto centers of Tamil Nadu and Maharashtra to industrial corridors in Gujarat and Punjab, small and large foundries alike depend upon reliable chemical allies to ensure consistency and quality.

Dealers in this space don’t just sell—you’ll often find them visiting plants, running trials, collecting sand samples, or offering guidance on curing times and temperatures. That kind of engagement transforms the relationship from transactional to transformational.

A Trusted Name: Jagannath Company

Among India's reliable names in this arena, Jagannath Company has gained industry respect with its commitment to quality, technical assistance, and timely delivery. Whether you operate a high-volume iron foundry or a specialty non-ferrous operation, they offer solutions customized to meet your individual requirements. Their emphasis on client relationships and real-world innovation earns them an asset to the casting process.

Humanizing the Supply Chain: Real-World Examples

A foundry with blowholes in castings

May find that the cause is gas evolution from old core binders. A good supplier won't simply blame—it'll provide a new, low-emission binder and assist with trial on a small batch before wide release.

A plant experiencing varying surface finishes

May want an improved quality of graphite coating. The dealer assists in identifying the correct viscosity and application process for their operation.

A casting line experiencing excessive rejection

May be utilizing additives that are not compatible with their melt chemistry. The proper partner will analyze furnace input, suggest a change in inoculant composition, and drastically enhance yield.

These are not merely "product sales" situations—they're instances of close collaboration that save money, time, and customer relationships.

FAQs: Demystifying Foundry Chemicals

1. What are the most vital types of foundry chemicals utilized in contemporary casting?

Some of the most important are foundry additives (such as inoculants and desulfurizers), core binders (e.g., resin-based systems), graphite coatings, and release agents. All serve a distinct function in enhancing casting accuracy, surface finish, and process efficiency.

2. How do graphite coatings enhance casting quality?

Graphite coatings are a barrier between mold surfaces and molten metal at high temperatures. They provide lower friction, assist in easier metal flow, and improve the surface finish. This translates to fewer post-processing operations and lower scrap rates.

3. What determines the performance of core binders?

The effectiveness of core binders is a function of sand grain size, moisture, binder ratio, curing conditions, and even pour temperature. An ideal binder must provide easy removal of the cores, good strength, and minimum gas evolution to avoid casting defects.

4. How do I choose the most suitable foundry chemicals supplier for my requirements?

Seek consistency in product quality, technical support, industry expertise, delivery capacity, and customer service. Ask for samples, try them out in plant trials, and gauge how thoroughly they comprehend your production issues.

Foundry Chemistry: Where Science Meets Craft

We always speak of casting as engineering—but it's chemistry, too. Molten metal doesn't respond the way you want it to just because you heat it up. It flows, cools, and solidifies depending on how you set up your mold, how your cores are designed, and how your chemical additives interact.

Having the right dealer guarantees you are not alone in understanding these intricacies.

The Bigger Picture: Sustainability and Innovation

With increased pressure to minimize emissions, employ environmentally friendly materials, and minimize scrap, foundry chemical allies are innovating more than ever.

-

Low-VOC binders

-

Water-based graphite coatings

-

Lightweight alloy additives

These aren't trends of the future—they're current. Partnering with a dealer who remains ahead of the curve puts your foundry ahead in performance and sustainability.

Final Thoughts: Your Success is a Shared Journey

The right chemicals don’t just make better castings—they make better foundries. They reduce rework, increase customer satisfaction, and boost your bottom line.

Whether you’re a small foundry scaling up or a large one optimizing throughput, your chemical dealer plays a central role in your success.